Lots has happened this week, but time is rapidly running out!

Last week we got TractorBot up and running with a hacked together chassis and did a comparison with last years entry. Something that became clear was the size, the new motors and large wheels made TractorBot 2015 wider than a sheet of A3 paper, thus too big to enter. There were a couple of options

- Revert to smaller motors

- Get smaller wheels

- Mount the motors closer together

- Modify the wheels to the offset was reduced

We really like the motors, they are not as fast as we hoped but are very powerful, therefore option 1 was out. The next three options however were all something we could work on.

First we tried out the smaller wheels, the ones we tried were from Rapid. With luck they had the same size hexagonal hub so they fitted straight onto the 3D printed hub converters we had made for the larger wheels. The wheels were quickly fitted and went for a test drive.

Apart from looking very strange, TractorBot was obviously a bit slower due to the smaller wheel diameter, but this has added advantages. It made the bot much more controllable and very precises. We feel this will make for a very good platform for the precision events such as three point turn and the proximity challenge.

The next option was to mount the wheels closer together, this is an easy win and will be incorporated into the next chassis design, more on this in a later post.

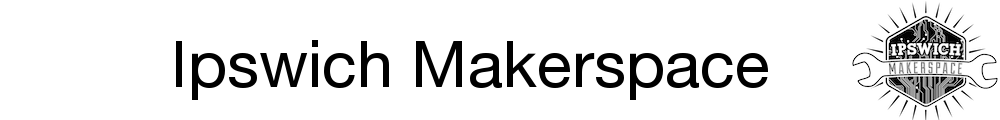

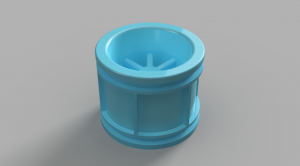

The final option would take a bit of effort but would help a lot in reducing the width of the bot. The current rims for the large wheels are designed in such a way that the whole wheel is offset to the outside of the hub fixing point. If the hub fixing point could be moved into the wheel then the wheel would start to overlap the motor shaft and create a smaller offset and thus a narrower bot.

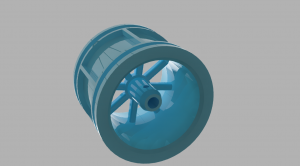

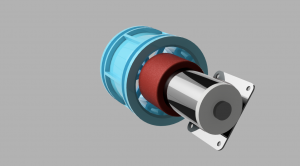

Since Phil had a 3D printer, Keith went off to design a new wheel, so out came the vernier gauge, off came the tyres from the original wheel and Keith duplicated the current wheel design into AutoDesk Fusion 360, this is free for makers and tinkerers and has some very nice features. The motors and hub adapter has already been modeled so Keith could put the three items together to make sure it all fitted together nicely.

- Wheel hub and motor

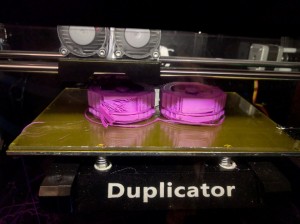

Everything looked like it was going to work so the STL file was created and sent off to Phil for printing. The printer was set running, it was a mammoth job and the software predicted that two wheels would take eight hours. The print button was pressed late one evening and left to run over night. Morning came and this was the result, just over half way through. It was lunch time buy the time they had finished.

Everything looked like it was going to work so the STL file was created and sent off to Phil for printing. The printer was set running, it was a mammoth job and the software predicted that two wheels would take eight hours. The print button was pressed late one evening and left to run over night. Morning came and this was the result, just over half way through. It was lunch time buy the time they had finished.

Keith learned quite a bit about how to produce a 3D printable optimised model, if we get time we will blog about this separately. But for now, the wheel basically works and gives the desired effect.

- The tyres fit

- Original wheel at the back, 3D printed wheel with smaller offset in the foreground

In summary, we now have a plan for making TractorBot fit within the size categorie for PiWars. Whilst doing so we have discovered we can 3D print our own wheels to our own specification and make them fit the tyres we already had. We also discovered that the robot was much more precise with smaller wheels. As such we now have the option to switch and change wheels to suit the task in hand. So now we need to carry on with the chassis design and start with the electronics. So much to do and so little time to do it.