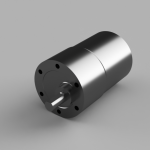

We were in the running. Our first choice and one of the most difficult always seems to be motors. With last year’s bot being too big we needed smaller motors and were initially drawn to these tiny metal geared ones from Pimoroni.

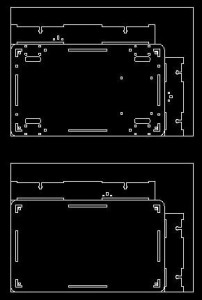

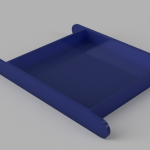

Keith’s ability with Fusion 360 allowed rapid prototyping of new robot chassis made from plywood, some 3D printed brackets, and testing of a new bot began.

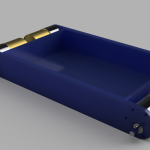

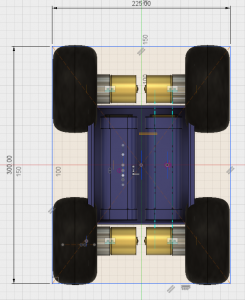

Unfortunately, the small motors were not up to the job and we needed a larger power plant. The motors eventually chosen were much beefier but that dictated the size of the final bot. With the new motors, Keith was able to model the components in Fusion.

Motors and batteries.

The size of the motors and our existing battery packs pretty much determined the size of the new robot chassis.

- Fusion 360

- Fusion 360

- Fusion 360

So now we have a chassis and Phil can get on and laser cut the next prototype…