Local Nerds Challenge Cambridge

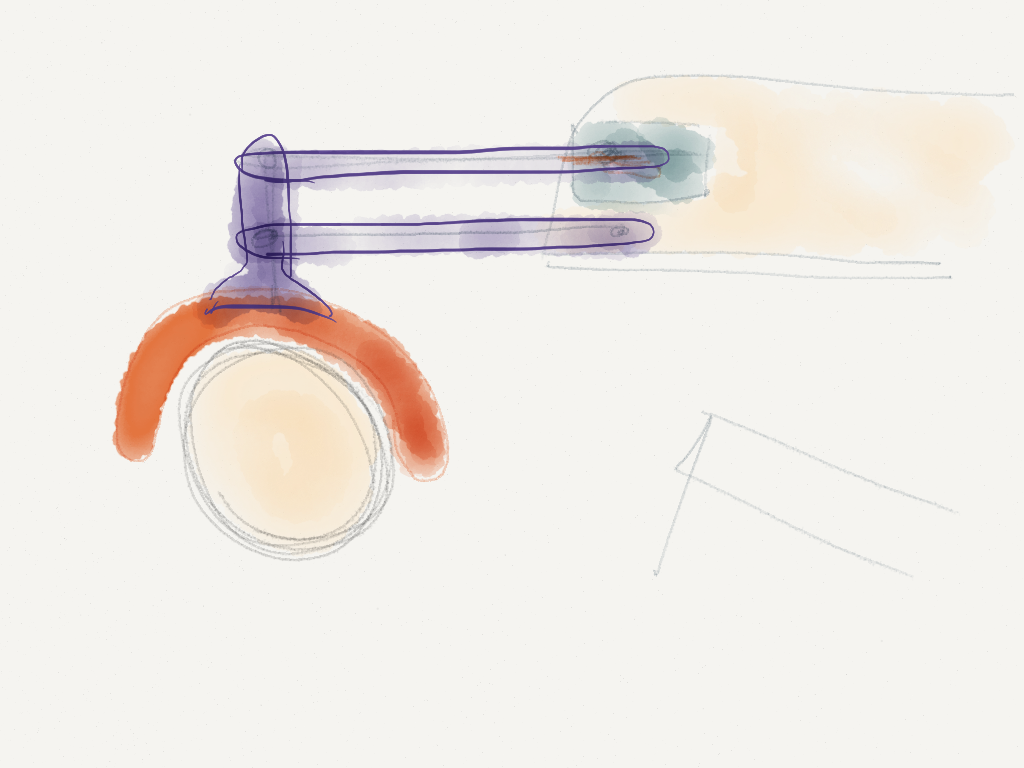

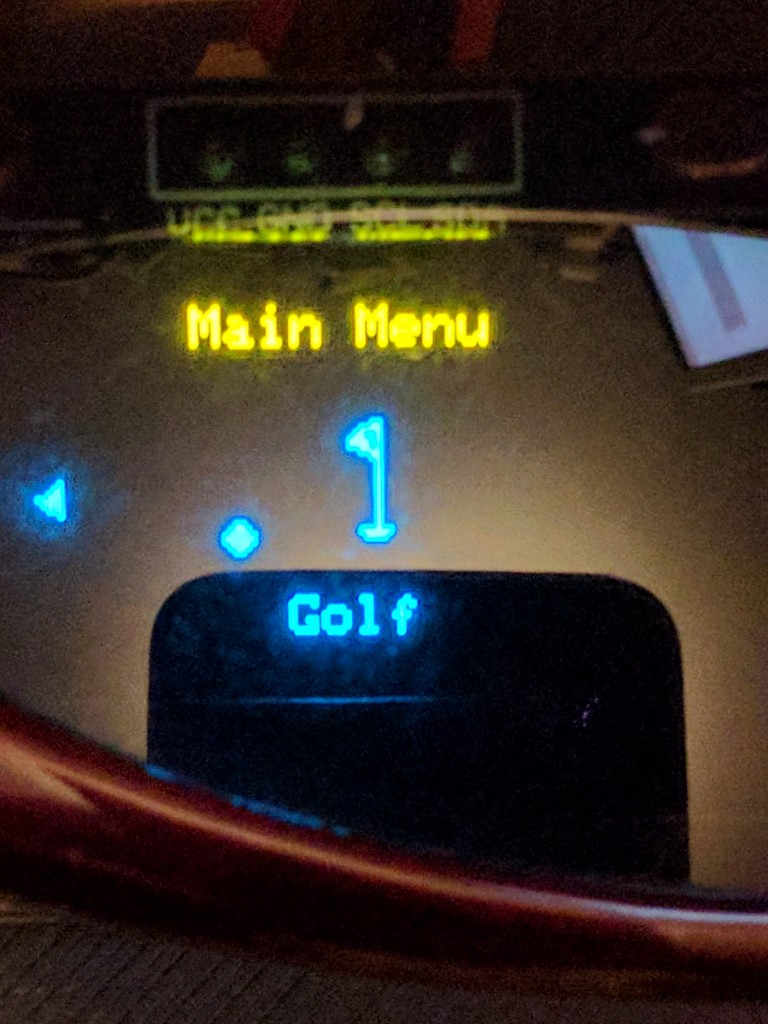

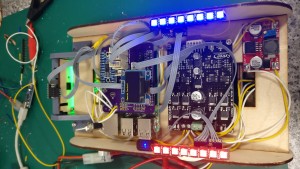

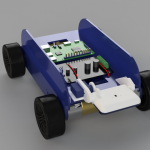

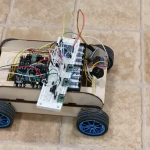

A local team of robot builders from Ipswich Makerspace took second place in the Cambridge PiWars competition at the weekend. They entered the Professional category in the prestigious robotics event, a challenge-based robotics competition in which robots created by teams compete in various non-destructive challenges. The Makerspace’s team competed on Sunday and got off to a rocky start getting knocked out of the Pi-Noon robot duel in the first round despite some skilful moves by the driver Jon Leach. They also had issues with the bright sunlight on the course for the Maze and Speed challenges. In training the robot had operated flawlessly under artificial light but the sun interfered with the sensors on the day. The team quickly recovered with an excellent run on the autonomous Line Following and a blistering time for the Crazy Golf with Phil Willis in control. A solid performance on the grinding Obstacle course boosted the team’s morale no end. The final challenge was to present the robot to be judged by Dr Lucy Rogers one of the judges from recent series of Robot Wars. Under Dr Rogers’ critical eye the team explained the highlights of their design helped by Phil’s 10-year old daughter Amy.

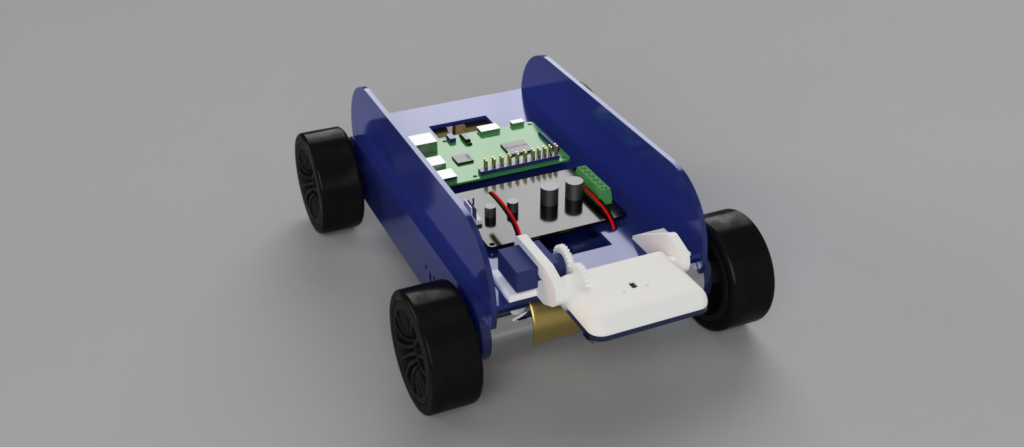

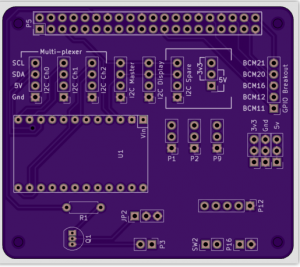

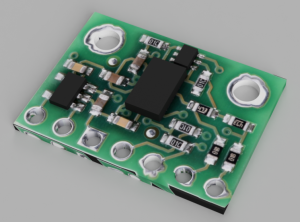

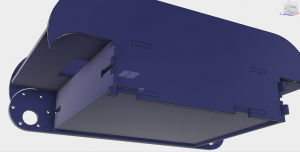

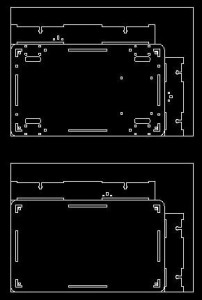

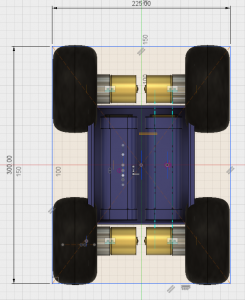

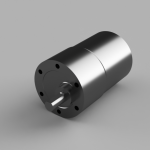

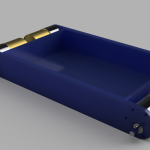

The team captain Keith Ellis said “It’s amazing what we were able to achieve with modern technology. Parts were laser cut and 3D-printed, we had custom circuit boards made and we even made use of Open Source computer vision software; 10-years ago we couldn’t have built this robot”.

Steve Chalkley from Ipswich Makerspace said “This was our third PiWars and we’ve been in the top three in each one. We’re very proud of our team and grateful to Rapid Electronics in Colchester for their sponsorship. It allows us to be more adventurous with our designs and produce winning robots”.

About the image:

Left to right: Keith Ellis, Dr Lucy Rogers (Robot Wars), Phil Willis (Amy’s Dad), Jon Leach. Front Amy Willis and Harrison Ellis (holding the trophy backwards, bless).

Background:

Dr Lucy Rogers is a chartered engineer, who appeared as a judge in the two most recent series of Robot Wars. She is a Chartered Engineer, Fellow of the Institution of Mechanical Engineers, the Royal Astronomical Society, and the British Interplanetary Society. Her current projects focus on reducing the damage from space debris. At the PiWars weekend Dr Rogers judged the technical and innovation elements of each team’s robot.

PiWars

Pi Wars is a challenge-based robotics competition in which Raspberry Pi-controlled robots are created by teams and then compete in various non-destructive challenges to earn points. There are prizes awarded at the end of the event. At the weekend teams from schools, families and groups of hobbyists competed for two full days of robotic fun and games. Pi Wars took place in Cambridge, UK and was open to anyone from around the world. This year there was even a team from the USA. It is run by the same team that organises the Cambridge Raspberry Jam.

Ipswich Makerspace

The Makerspace is a collaborative workshop and community space for creative people to work, gain new skills and inspire each other. After three years of hard work the group now has its own premises in Dove Street which they are filling with high and low tech tools for budding makers. They organise a range of activities such as the regular Thursday project night. The team from the Makerspace has entered all three of the PiWars competitions winning one and coming second in the other two, a fantastic achievement given the level of the opposition. (Website: www.IpswichMakerspace.com)

Raspberry Pi

The Raspberry Pi Foundation was launched in 2008, in order to endorse and develop the Pi. On February 2012, the Raspberry Pi 1 Model B launched at just £25, and offered a 700MHz processor, 512MB of RAM, two USB ports and a GPU capable of 1080p display – all in the palm of your hand. Recent Raspberry Pi sales figures show that the humble board is, in fact, the world’s third best-selling general purpose computer after the Mac and PC. Raspberry Pi achieved this milestone by selling north of 12.5 million boards in five years. This figure beats the previous third place holder, the Commodore 64. What seems like a simple creation went through an arduous journey on its way to becoming the best-selling UK-developed computer in history. (Source: www.raspberrypi.org)