In this adventure I attempt to get the Roland Camm-2 2300/A CNC machine to mill a PCB into some copper board. This is what the temporary setup looks like. I have the CNC machine, laptop, and an old XP machine.

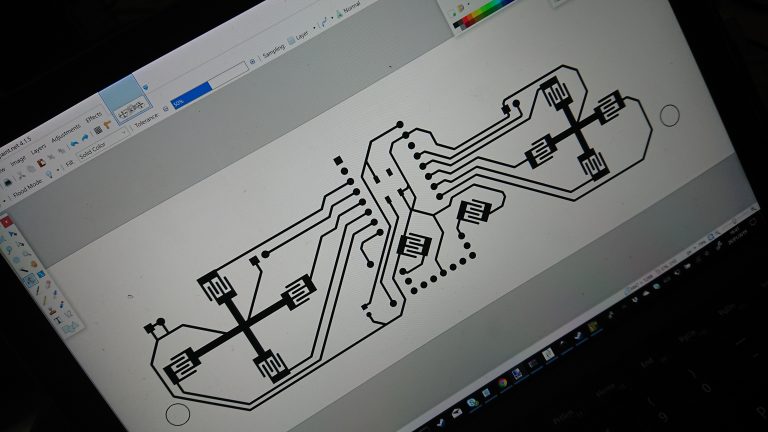

We have procured a set of tools for the Roland specifically for milling and drilling PCBs. I started by testing on some polystyrene (as in the above), which seemed to go OK so I thought I would move to my PCB project. I took the Copper layer and converted it to a bitmap such that Dr Engrave can import it. It was at this point I knew I was in too deep and it could only go wrong.

I stuck down the copper board with some double sided tape. After some fiddling with the tool settings and trying to position the tool itself correctly on the Z-axis, I pressed the “print” button and closed my eyes! There was not too much I could do at this point, it was either going to start neatly cutting out the tracks or crash into the end and start eating itself. My polystyrene test did not fill me with any more confidence, but my hand was positioned over the emergency stop button.

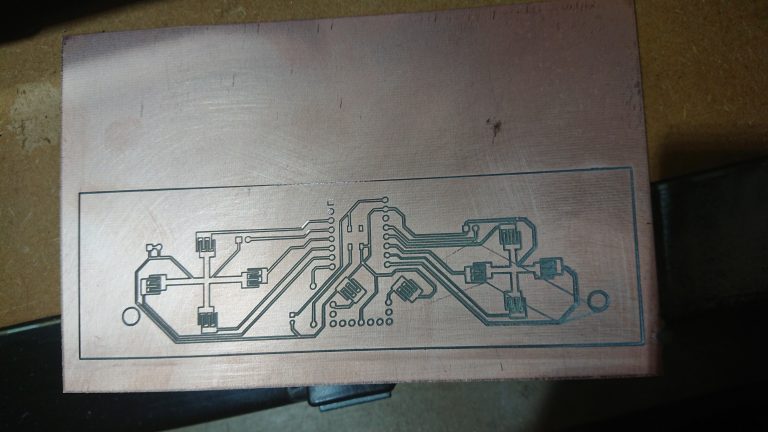

After a few minutes of whirring and buzzing, I was presented with this (below) 🙁

It’s not what I expected, but for my first attempt I suppose it could have been worse. Let me take you through it.

- Its not cut evenly at all, there must be some severe levelling problems with the bed and/or the material

- The tracks are very thin and pretty wobbly looking

- The tool hasn’t lifted off properly and has wiped a skid mark across it

- The pads are very small and wont take drilling without disappearing entirely

- The “toothed” button pads are a mess, one is just a gaping hole

Next steps are to:

- Get a fatter tool to mill the wooden bed flat

- Make a jig and/or test sticking down the copper much flatter

- Redesign the layout with fatter tracks that are father apart

- Test cutting out the edge cuts

- Test drilling to through holes

- Try again

Thats all for today, I will keep you updated on the progress.

Nice work Mal, well done.