The third member of the team, Jon, had taken the lead on the software design. He started with our original TractorBot 2015 software and restructured it, to allow better collaboration via GitHub. Jon has created several useful libraries for the Pi and if you are interested you should check out his github page. https://github.com/leachj

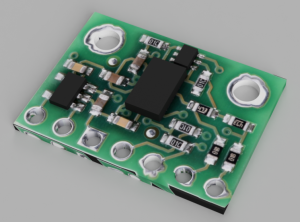

Jon already had some good ideas for how to give the robot senses to allow it to navigate the maze, and so purchased some Time of Flight sensors. We used these magical I2C devices in 2015 to keep our speeding robot from crashing into the walls when it came to the straight line challenge. Don’t just take our word for it…

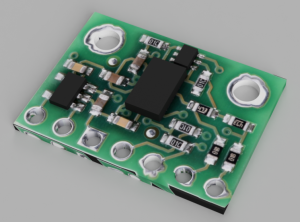

The VL6180X Time of Flight Distance Ranging Sensor is a Time of Flight distance sensor like no other you’ve used! The sensor contains a very tiny laser source, and a matching sensor. The VL6180X can detect the “time of flight”, or how long the laser light has taken to bounce back to the sensor. Since it uses a very narrow light source, it is good for determining the distance of only the surface directly in front of it. Unlike sonars that bounce ultrasonic waves, the ‘cone’ of sensing is very narrow. Unlike IR distance sensors that try to measure the amount of light bounced, the VL6180X is much more precise and doesn’t have linearity problems or ‘double imaging’ where you can’t tell if an object is very far or very close.

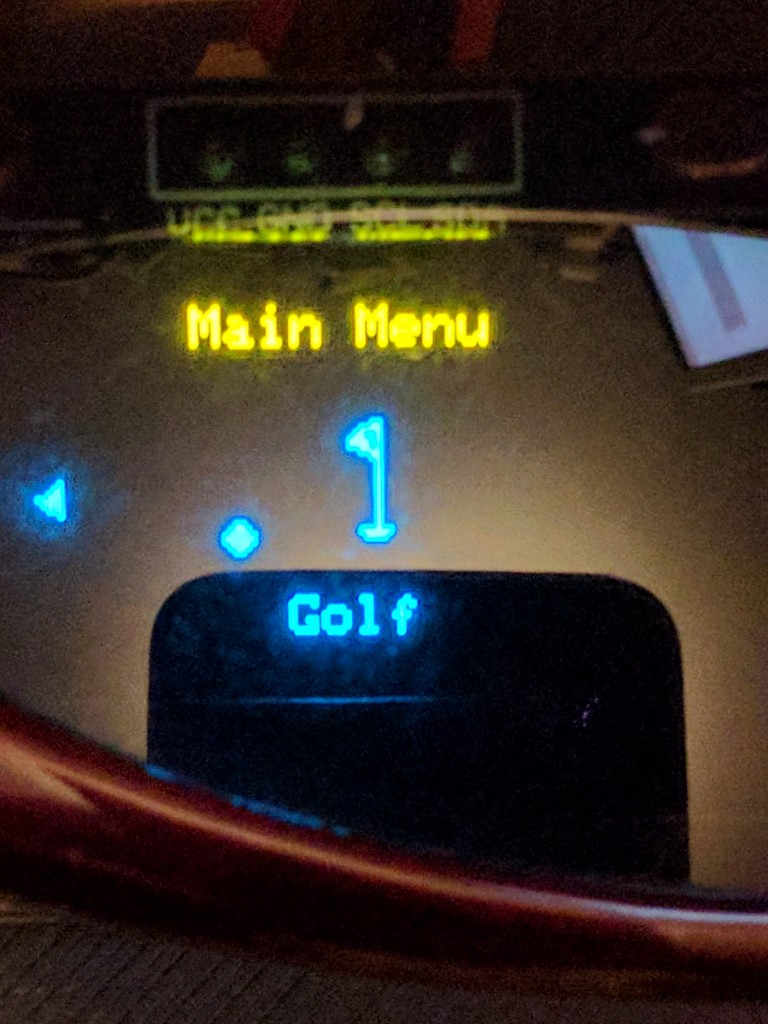

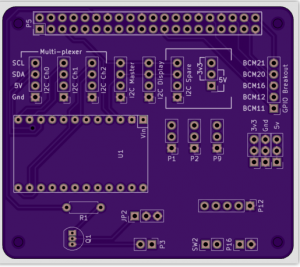

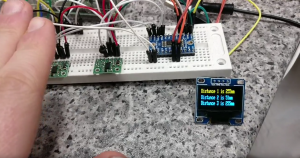

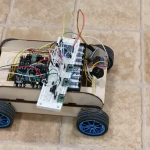

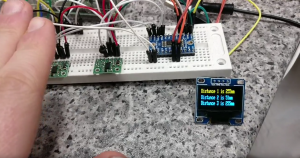

Jon set to work improving his VL6180 sensor library and bread boarded 3 sensors using an I2C multiplexer unit from Adafruit to complete the test rig. While his credit card was in his hand he also purchased a small OLED display so we could select the current challenge mode. It’s a really cute display and very clear, just wait until you see it in real life. The menu system even has tiny icons!

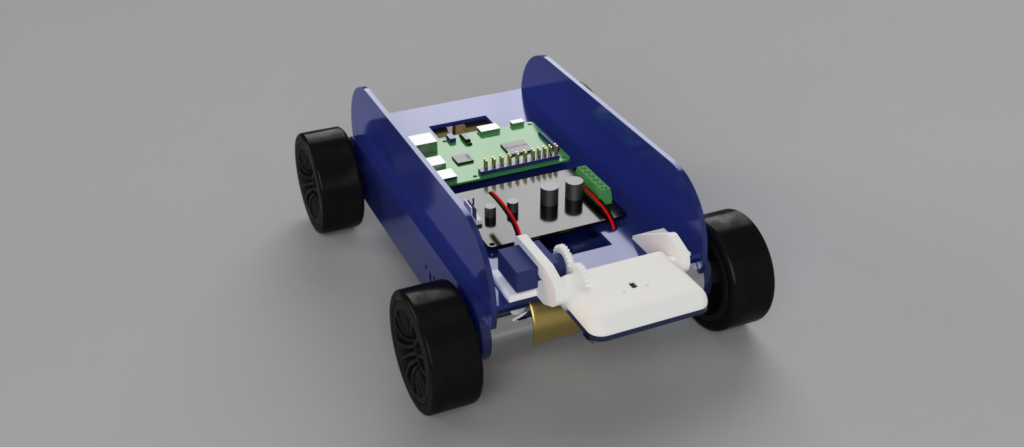

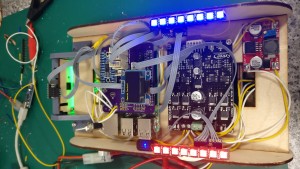

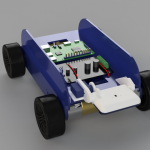

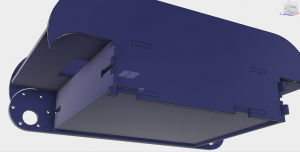

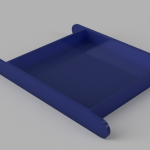

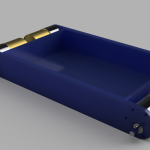

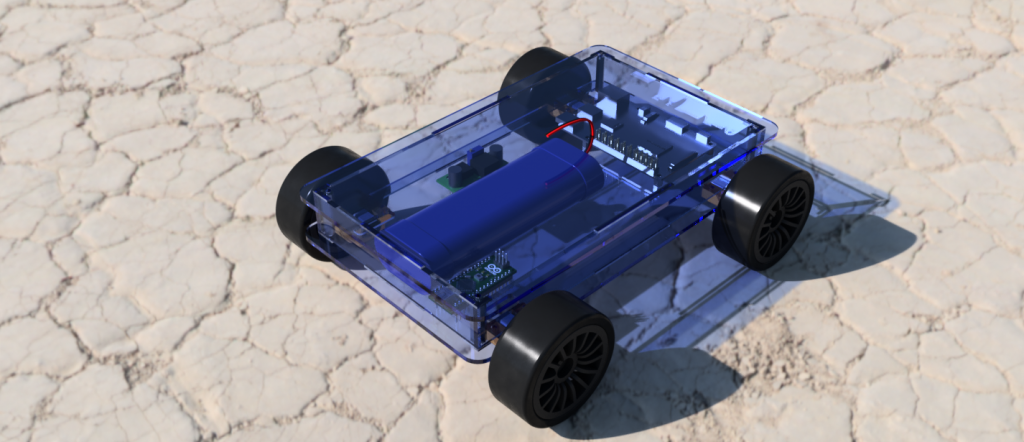

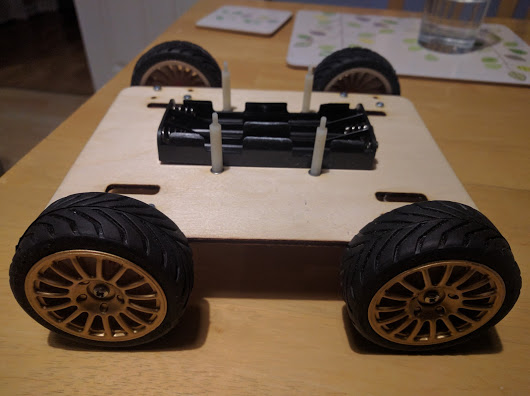

While Keith’s beautiful renders look fantastic, the reality is that once you start hooking up the wiring what was a sleek machine begins to look more like a rats nest.

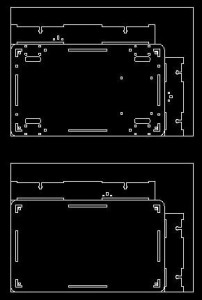

What to do about all those wires…